Design

Waterproofing design should be undertaken by a suitably qualified person and be appropriate for the specific performance required.

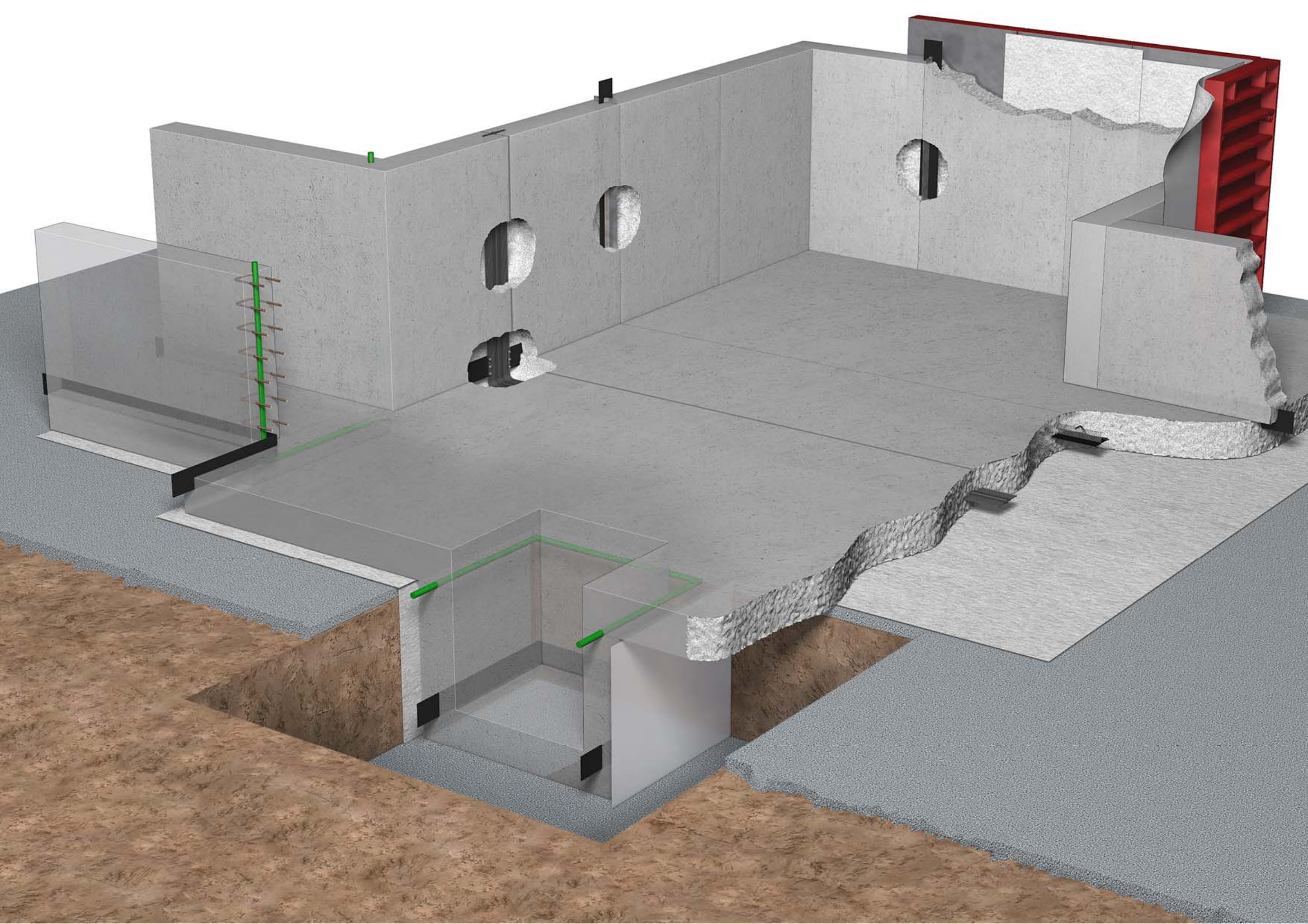

The performance or ‘Grade’ (level of waterproofing protection) required will guide the selection of which ‘Type’ of waterproofing is best suited to achieve a successful outcome.

Three

waterproofing Grades:

-

Grade 3

-

Grade 2

-

Grade 1

Grade 3

Habitable accommodation – ‘No water penetration acceptable’

*Grade 3 waterproofing protection is required the waterproofing design should include a combination of two of the types of waterproofing systems.

Grade 2

Non-habitable areas – ‘No water penetration acceptable though damp areas are tolerated’

Grade 1

‘Some seepage and damp areas are tolerable, dependent on intended use’. Drainage may also be required to deal with seepage.

Our in-house technical team can offer the expertise of a Certificated Surveyor in Structural Waterproofing (CSSW).

Let’s talk